Customer Case Studies

Customer | Ivars, Italy

Requirement | Replacement air cell for seat waterfall.

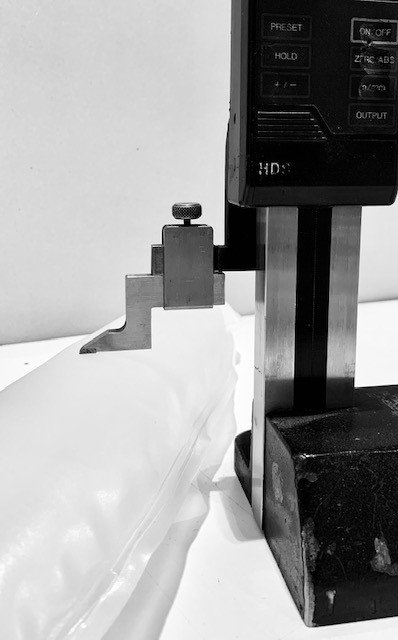

Development Process:

Ivars contacted us because they were developing a new seat and wanted to introduce a new comfort level on the front waterfall of the seat. They had tried polyurethane materials of various shore hardness but could not find the result they required. We advised them that we could make some non-adjustable air pockets or cells that could be shaped to fill the gap they required.

We then filled the cells to various air levels and supplied samples for the Ivars product designers to trial. Once the air pressure was agreed, tooling was completed within 2 weeks and at minimal cost.

The Result

They were extremely happy with the results and the product will now be marketed globally with the first ordered supplied.

Customer | Nomique, UK

Requirement - Additional kidney support in task chair.

Development Process:

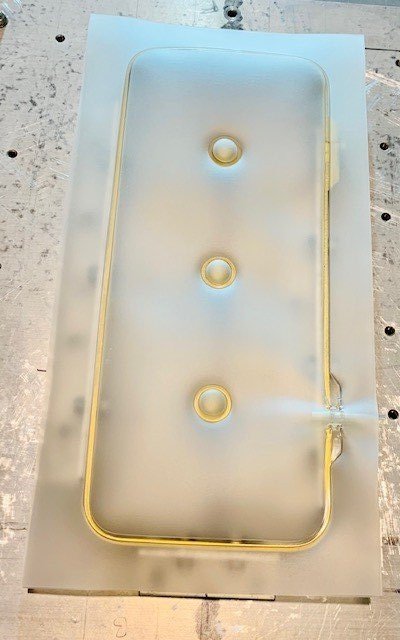

Our customer was happily using our standard back lumbar on a number of different models within their range. They did, however, have a customer request for additional lumbar and kidney support on one specific model, but without the addition of more cells and bulbs.

We developed a product for them based on a standard lumbar cell but introducing a set of circular welds or "teardrops" that limited the cell expanding in the centre, redirecting air to the sides of the cell thus giving additional kidney support. Samples were produced within a couple of days and were approved by the customer before we developed a specific tool for them at minimal cost.

The Result

We were delighted to help our customer Nomique in meeting their customer's needs, this has resulted in strong sales for Nomique for this bespoke offering.

Customer | Repose Furniture, UK

Requirement - Investigation into the capability of inflatable air cells to help prevent pressure sores developing in specialised seating.

Development Process:

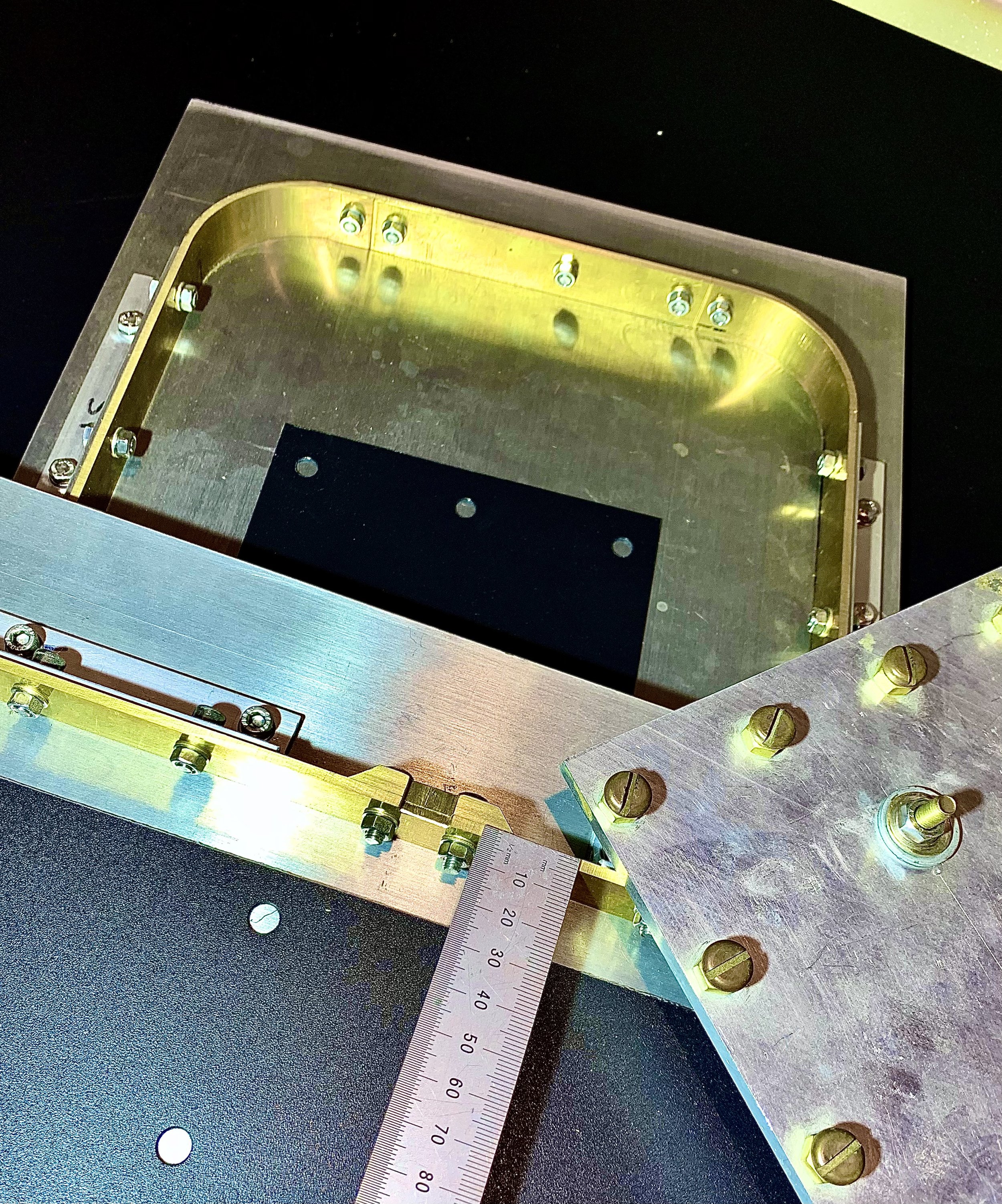

We embarked on this development process not knowing if we could help Repose Furniture to investigate other methods of providing support in their chairs, other than using dense and cumbersome foam.

We discovered that we could make large 2-dimensional air cells that could be adjusted to the comfort of the end user. Working in collaboration with Repose and using pressure mapping technology we found that we could indeed provide a useful product in different sizes (backs, seats and footrests) that helped in pressure management.

The Result

These products have gone on to be a very useful addition to Repose Furniture's range, making extremely well-made and comfortable furniture even more adaptable to the requirements of their clients.